When it comes to manufacturing precision plastic components, consistency is key. Whether you are producing a single prototype or thousands of parts for a large-scale production run, achieving uniformity in your injection molded parts is essential. In this article, we will explore the strategies and techniques that can help you maintain consistency in your plastic injection molding service.

Understanding the Importance of Consistency

Consistency in injection molding refers to the ability to produce identical parts repeatedly, adhering to the same specifications and quality standards. Achieving this consistency is vital for these reasons:

Cost-Efficiency

Uniformity in production leads to less material waste and lower production costs. It also minimizes the need for rework or adjustments.

Customer Satisfaction

Consistent parts result in reliable products, which in turn lead to satisfied customers who can trust your brand.

Methods to Achieve consistency

Now, let’s delve into the methods to achieve this level of consistency.

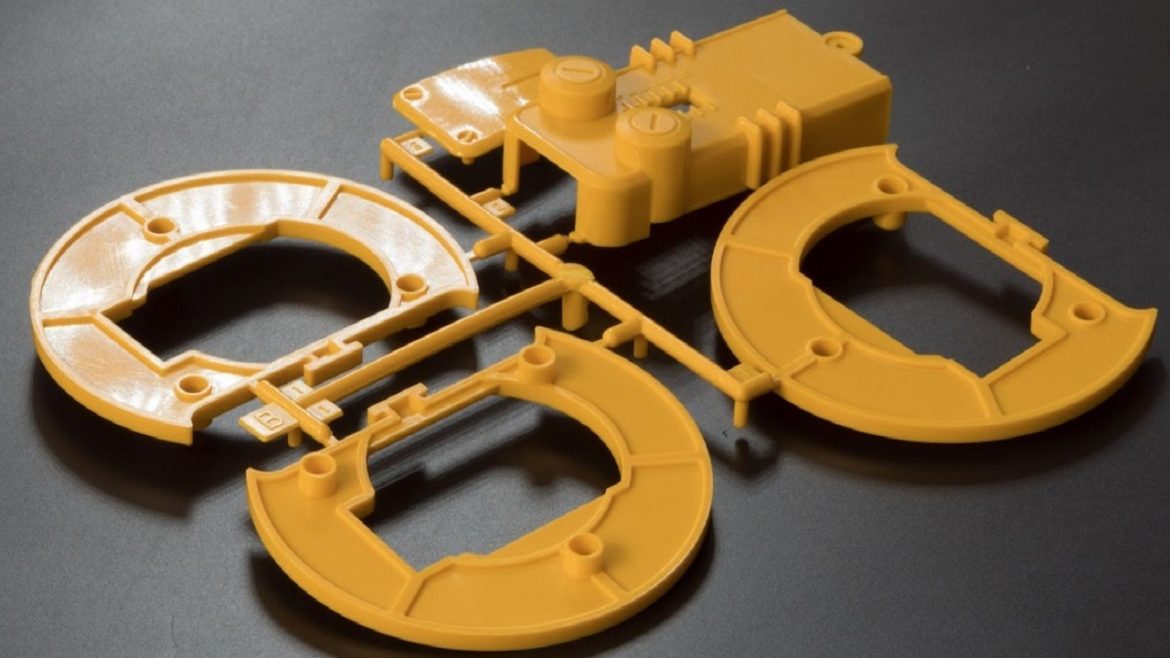

Robust Design and Mold Planning

Consistency begins with the initial design and mold planning stages. A well-thought-out design and mold design can significantly impact the repeatability of your production process. Here’s what to consider:

- Design for Manufacturability (DFM): Implementing DFM principles ensures that your part is optimized for the injection molding process, minimizing design-related inconsistencies.

- Mold Design: Work closely with mold designers who understand the intricacies of injection molding to create molds that promote uniform flow and cooling.

Material Selection

The choice of material is critical to achieving consistency. Select a material that suits the application’s requirements and is readily available in a consistent quality. Understand the material’s properties, including shrinkage rates, to account for them in the design and production process.

Machine Calibration and Maintenance

Regular calibration and maintenance of injection molding machines are imperative. Precise control over temperature, pressure, and cycle times is essential for consistent results. Routine checks and adjustments help prevent variations in the manufacturing process.

Process Control and Monitoring

Implement strict process control measures and continuously monitor key variables during production. This includes monitoring temperature profiles, injection pressure, and cycle times. Automated systems can help maintain precise control and reduce human error.

Quality Control and Inspection

Incorporate comprehensive quality control and inspection processes into your production line. Regularly inspect and measure parts to detect variations or defects. Address any issues promptly to maintain consistency.

Operator Training

Well-trained operators play a crucial role in achieving consistency. Ensure that your team understands the intricacies of injection molding, the specific requirements of your products, and how to operate the machinery effectively.

Data Analysis and Optimization

Collect and analyze data from each production run. Identify patterns, variations, and potential areas for improvement. Use this data to optimize your processes continually.

Conclusion

Consistency in injection molded parts is not an accident but the result of meticulous planning, precision, and continuous improvement. By focusing on design, materials, machine maintenance, process control, quality assurance, operator training, and data analysis, you can achieve the level of consistency necessary to produce high-quality plastic components consistently. This commitment to uniformity will benefit your business by reducing costs, increasing customer satisfaction, and ensuring the reliability of your products. Whether you are creating prototypes or engaging in large-scale production, consistency is the hallmark of a successful plastic injection molding service.