CNC milling is an essential part of the manufacturing world today. It can be used to develop complicated 3D shapes or apply features or machined surfaces to metals and plastics. The CNC milling process is accurate, and its processes are repeatable. The CNC milling technologies serve several industries. You can apply the milled parts in different sectors of the economy. This post aims at informing you of the CNC milling application in the medical sector.

CNC milling application in the medical sector

1) Body Implants

CNC milling can be used in the medical field to make body implants. Body implants such as hip replacement or knee implants need a high degree of accuracy and precision. Any mistake made during the manufacturing of body implants can impacts a patient’s life tremendously.

The advantage of using CNC milling services is that it provides a high degree of accuracy in a patient’s specific body craft as it achieves tolerance of 4μm. A CNC milling factory develops a CAD model after getting instructions from an orthopedist.

Through CNC technology and reversed engineering, it recreates the body part. The body implants are created using biocompatible materials such as titanium and PEEK. The advantage of a CNC milling machine is that it is compatible with many materials.

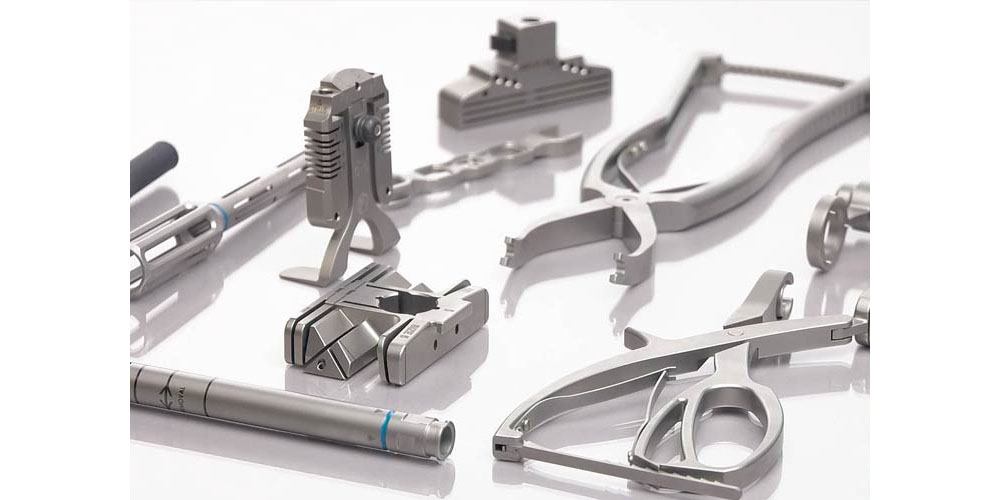

2) Manufacturing medical instruments

CNC milling helps develop medical instruments such as surgical scissors, blades, spacers, biopsy, and several other least invasive medical tools or surgical tools. The medical sector depends heavily on CNC milling services. The reason for the dependence is that CNC milling machines are simple to understand. CNC milling machines can manufacture big volumes of replicated medical instruments in only a few hours, while 3D printing may take days to finish.

3) Electrical medical equipment

Many medicals devices such as X-ray machines, heart rate monitors, and MRI scanners have many CNC milling machined electrical features. Examples include; buttons, levers, switches, and electrical casings and housing. Electronic medical instruments do not need to be created by biocompatible materials like surgical tools and medical implants.

The reason for this is that they do not touch any internal organs. The manufacturing of electronic medical equipment is made under strict restrictions and supervision by the regulatory body in charge. The milling factory’s non-compliance with the regulations and requirements can lead to hefty fines. It can also go as far as imprisonment. Sometimes even the medical practitioner who procured the service losses their license.

How to choose a CNC milling factory

1· The factory that meets all the requirements

A certified CNC milling factory that follows the regulatory and statutory requirements is an excellent factory to choose. Also, a CNC milling factory needs to follow the quality management system’s quality standards for sectors such as the medical industry.

2· Highly experienced quality control experts and engineers

CNC machining services are flooding the market. For sectors such as the medical industry, quality is essential. When choosing a factory to outsource your service, it is better to select one that has experienced experts.

Conclusion

Some milled parts, such as medical tools, are significant in the market. The benefit of using CNC milling processes is that it helps develop high-precision parts according to your exact specification.