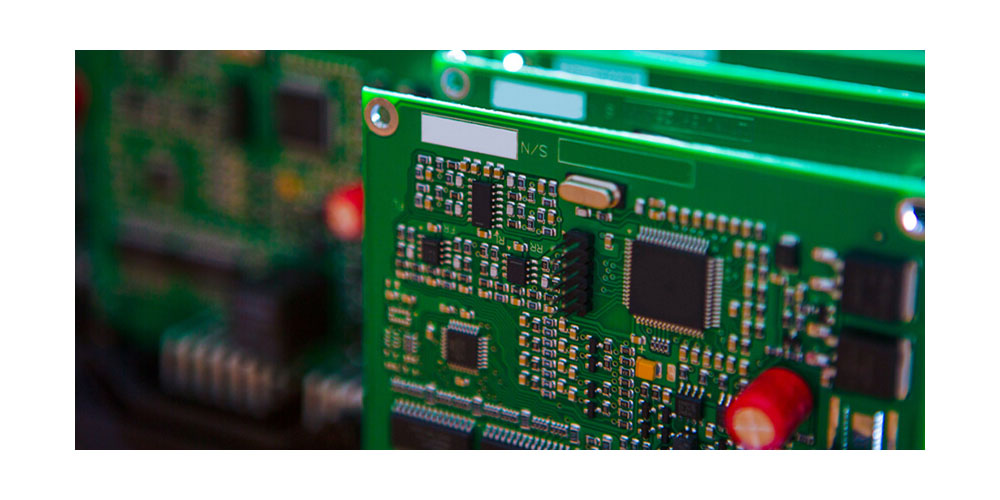

The PCB manufacturing process is a process that leads to the development of a PCB that is Printed Circuit Board. One of the most common uses of PCB is to ensure that electrical devices function correctly. Furthermore, the manufacturing process is straightforward. Additionally, different machines are used in the production process. Therefore, if you proceed to read this article, you will learn of seven PCB manufacturing machines used in the production process.

Seven PCB manufacturing machines used in the production process

1. PCB drilling machine

As the name suggests, the PCB drilling machine is used to drill holes on multilayer or single-layer printed circuit boards. The latest innovations in electronic machinery and computer technologies allow for automated drilling processes. Therefore, the latest PCB drilling machine innovations ensure that less labor is used and less time is spent drilling. Furthermore, the PCB drilling process is crucial in the PCB creation process.

2. PCB brushing machine

The PCB brushing machine’s primary purpose is the cleaning and deburring of drilled PCBs. The device uses a high oscillating frequency to brush the thin inner layers bi-directionally. Furthermore, the device allows for an adjustable distance between the panel and brushes. Also, the copper centrifuge in the machine helps in removing copper abrasions from the rinsed water. The brushing machine is commonly used in stainless steel, aluminum, copper, and so many others. Additionally, the device is easy to operate and has minimal maintenance costs. The machine is also available in different shapes, colors, and sizes.

3. Wave soldering machine

As the name suggests, a wave soldering machine is commonly used for soldering. Furthermore, the device is vital for PCB assembly processes, especially those that require high-volume production. The wave-soldering machine is divided into several parts: preheater, conveyor belt, flux sprayer, and molten solder pan. Additionally, the automated machine allows for mass production.

4. Reflow oven

The reflow oven machine is used for the soldering of the PCB boards. The device uses many surface mount features to ensure that the processes are undertaken effectively. Furthermore, the machine must ensure that the surface mounts electrical parts are soldered to the PCB through reflow soldering. There are two common types of reflow oven machines in the market: vapor phase oven and convection and infrared ovens.

5. PCB cleaning machine

PCB cleaning machine removes flux and resin remains from hybrids, populated boards, and associated production residues. The device ensures that PCB cleaning in the assembly process is water-free or semi-aqueous.

6. Solder paste printing machine

The solder paste printing machine is used for mixing flux vehicle and solder tiny alloy particles. The device ensures that the challenges of printing on a bare SMT PCB are entirely eradicated. Furthermore, the machine ensures that solder paste is printed on the Surface Mount Assembly (SMA), thus develop a PCB with the help of stencils or metal mesh.

7. Pick and place machine

The pick and place machine purpose is to lift parts of a PCB, rotate them in the right direction and then put them on a PCB board.

Conclusion

The PCB manufacturing process requires the help of different machines to ensure that all PCB components are effectively situated. The various devices participate in ensuring that PCB quality is attained. Thus, the above machines are very crucial in the PCB production process.