If you have a business you wish to expand with some new products, it might be a great idea to use prototypes to obtain funding or to create interest in your products. Here, you’ll learn everything you need to know about prototype manufacturing and why they are beneficial.

What Is A Prototype?

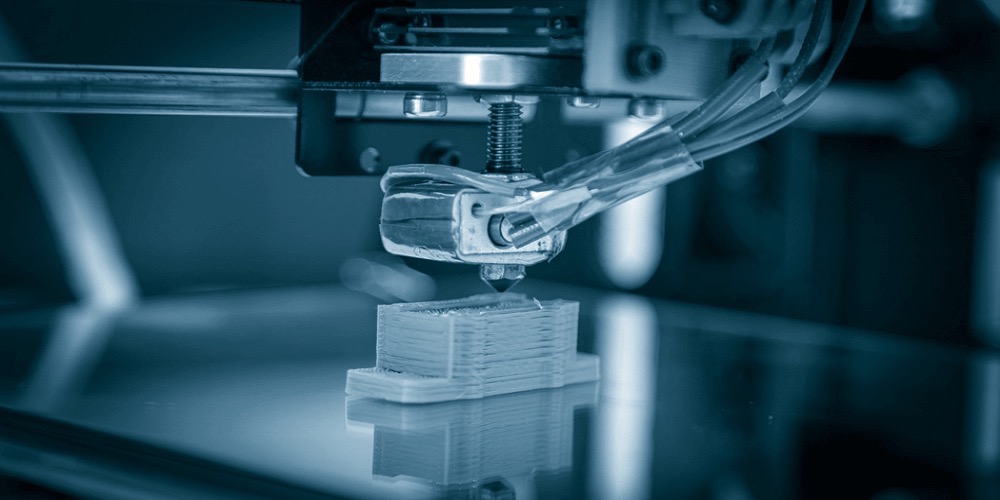

Prototypes are generally used by all types of industries. However, in the manufacturing industry, a prototype refers to a model of a product that serves as a guide in developing the actual product. The prototype isn’t a finished version of the product but it does help to show that the design is possible and it displays the aesthetics of the design. If you’re looking at producing new products, a prototype helps you receive feedback from customers, distributors, and your stakeholders.

Categories of Prototypes

There are different stages of manufacturing and the different categories of prototypes provide feedback to these stages. Each category of a prototype looks different and serves a different purpose. The benefits of the different categories of prototypes also differ during the stages of manufacturing. Prototypes can be made from different materials and can have a different look from the finished product.

· Proof of Concept

This type of prototype serves to test the design function of a product and not full functionality. The purpose of this prototype is to check if the right materials are used and that the product performs as expected. The major advantage of using this prototype is that you can make design changes before you start the manufacturing process, thus saving you a lot of money and time.

· Visual Prototype

Just as the name suggests, a visual prototype only focuses on the appearance and size of the finished product. It, however, does not test the functionality of the product. Usually, this category of prototypes is used for marketing purposes. A part of this category of prototypes is the Form Study prototype which only focuses on the geometry of the product’s design, but not other aspects such as product texture or color.

· Working Prototype

This prototype emphasizes the functionality of the finished product but not on its final appearance. The prototype checks if the final product will function optimally. Here, you can also change the design to improve or optimize the final product’s functionality.

· User Experience

This prototype does not have the full appearance and functionality of the finished product but it has just enough to be used for end-user research. The purpose of this prototype is to check if the product is user-friendly and to know what customers feel about the product, the data received help to make improvements in the product.

· Functional Prototype

This prototype has the complete look and functionality of the final product. However, the material and techniques used to make this prototype might differ from those used for the final product. It can even be on a different scale than the final product. Usually, this prototype is used to get funding for the production of the final product.

Conclusion

Prototypes are forever changing and shaping the manufacturing industry. Having a good idea of how it works will help you to make the right decision for your business.