CNC machining is a technique of manufacturing where computer inputs are used to control tools like drills and lathes. These tools are known as machining tools. CNC machining is applied in a wide range of industries for various machining projects. One of these projects is CNC prototype machining. 3D printing has for years been a dominant technique for rapid prototyping. However, in recent years, CNC machining for rapid prototyping has also become prevalent.

Reasons why CNC machining is suitable for prototyping

There are numerous reasons why companies in varying industries use CNC machining for producing prototypes. Below are some of these reasons;

1. Repeatability

CNC machining starts by creating a part from a computer file. This means that the engineers make designs that can create a final part with the exact dimensions as the design. This is the main reason why the degree of repeatability is high. Repeatability is essential because, in prototyping, you may have to create a prototype severally until you reach perfection. With CNC machining, you don’t need to start creating the prototype design from scratch each time. All that is required is adding a few new dimensions to the design and create a new prototype. This element allows you to make quick and precise alterations.

2. Comparability

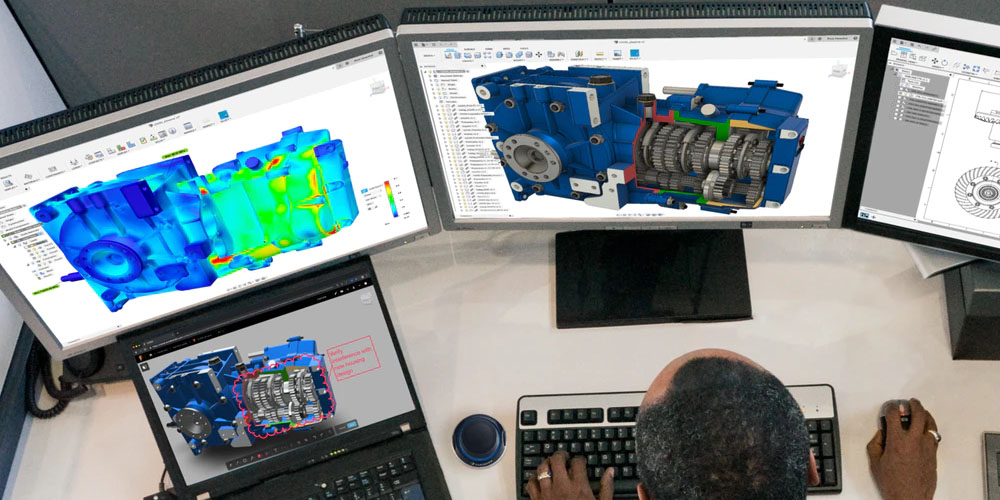

In addition to making quick and precise alterations, you can also compare the different prototypes effortlessly. All an engineer has to do after making the alterations to the design is to make a side-by-side comparison. You can also use simulation software to test the performance of the prototype in the real world.

3. Quality

While computers are not perfect, you usually make fewer errors than the latter. Computer-controlled machines usually function precisely as they are designed to. The only time that they do not do this is when the machines break down. These machines usually follow instructions 100%. This means that they produce high-quality prototypes.

4. Consistency

Computer-controlled machines can repeat operations over and over again without worrying about quality. This is because of the consistency of the machines. Although most companies only need one prototype, the consistency of these machines leaves the door open for two and more if needed.

5. Wide range of materials

Prototyping with CNC machining is also beneficial because you can use a wide range of materials. This is vital if you are looking to use the most robust materials. CNC machining allows you to find compatible, strong, and durable materials, including metals. This is a benefit that 3D printing does not offer.

6. Ability to create prototypes similar to the final product

CNC machining also allows you to create parts that are similar to the final product. This is possible because of the designing process. 3D printing, the primary competitor for CNC machining in rapid prototyping, does not offer this benefit.

Final word

CNC machining for prototyping allows companies to create prototypes that are close in appearance and behavior to the end-user product. This element makes it easy for them to move to final production. Additionally, it reduces the costs since there are fewer changes to be made.