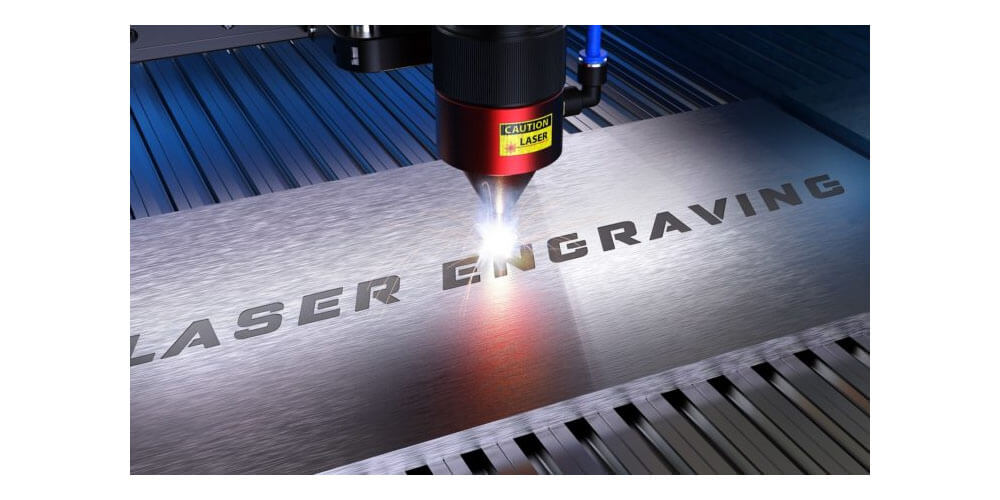

Laser engraving is continuing to catch the eyes of several manufacturers in different industries. The subtractive manufacturing technique uses a laser beam. That beam changes the object’s surface. Laser engraving printing manufacturing is commonly used in image creation. It is applied to a material that can be seen at a person’s eye level. To know more about laser engraving printing manufacturing, click here www.laserengravingmanufacturers.com.

Major Particulars of Laser Engraver Printing Manufacturing

To use the subtractive printing method, the laser will create a high heat to vaporize the matter. This should expose cavities to form the end product (image). Engraver printing is quick. Note, a laser method is used to remove the material using pulses. The depth of the activity is controlled by the frequency with which the laser beam passes on that material.

Laser engraving machine types

The laser engraving industry has different machine types. The first one has a stable workpiece stay. Therefore, the laser moves inversely. Then there are machines dedicated to a variety of cylindrical workpieces.

The last possibilities involve the laser engraving machines in which the laser, as well as the workpiece, are not mobile. However, the galvo mirrors often move such that the laser beam is appended to the beams.

What are the possible uses of laser engraving machines?

Laser engraving printers are used on metal, wood, in addition to plastic. It can also be used on glass surfaces. Further, it is effective than the conventional engraving for smaller objects including jewelry.

Then, there are smaller to no chances of deforming material. This means that the mechanism can also be used for different applications, including medical devices and fine art. Laser engraving can be used in industrial applications.

It is also possible to apply the trick to your DIY laser engravers. For instance, you could use a CO2 laser system. Connect it to the engraving machine located on your computer’s USB. This should serve as a printer.

Features of laser engraving technology- what makes it unique

Laser is a term used to mean Light Amplification by Stimulated Emission of Radiation. A laser machine has three main properties. These elements are used to create a permanent marking on different materials. The materials include:

a. Outstanding directivity

In laser’s outstanding directivity, the element light waves travel in one line. Light does not spread apart. Ordinary light sources will emit light waves. These elements spread out across different directions but the light wave from a laser beam is of the same color.

b. High coherence

In high coherence, the waves are in direct phase with one another. The laser machine has three main parts- the controller, the laser, and the surface. In high coherence, the laser machine works like a pencil that emits monochromatic beams. These beams allow the controller to be in a position to trace the patterns to the surface.

c. Outstanding monochromaticity

In laser monochromaticity, the laser’s wavelength travels in a straight line. The beam is narrow. Therefore, the wavelengths spread conventionally making it possible for a manufacturer to print several copies of the elements that need to be engraved.

Final Thoughts

Lasers are special. They print high intensities of materials. Besides, lasers are also outstanding monochromatic sources of light. And unlike the classical sources of light, a laser can easily oscillate in one spectral.