CNC milling is a subtractive manufacturing process. It starts with the creation of a CAD model and feeding instructions to the CNC milling machine. The market features a wide range of CNC milling techniques. One of them is the 3 axis CNC milling technology. In this post, we look at 3 axis CNC machining and how it works.

What is 3 axis CNC machining?

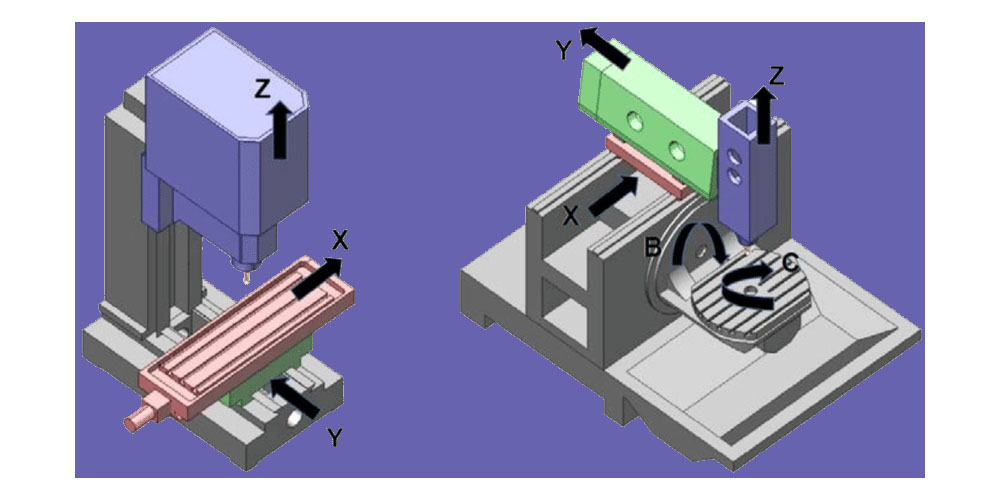

This is a type of CNC machining tool that uses three axes that work simultaneously. The three axes are X, Y, and Z. They perform the following functions;

- X- this axis is responsible for the back to from movement of the workpiece

- Y- this axis is responsible for the side to side movement of the piece

- Z- this is responsible for the up and down workpiece movement

How does a 3 axis CNC milling machine work?

Here, the cutting tool is held either horizontally or vertically. The cutting tool is then spun as the piece is held in place. The three axes move simultaneously. This means that you have the freedom to create complex parts with better efficiency.

The machine works by shaving and cutting parts from your workpiece, which is the raw materials. You cut off the materials that are not needed on the part. The too is then allied with your material through multi-access milling and machining. From there, the material is worked on down to the desired shape and size. As mentioned earlier, the part does not move. The tool moves as the part remain stationary. The movement involves two linear challenges and a cutting head. It also consists of a spindle on one axis, which works together with the other two axes.

The functioning of the tool head differs from one machine to the next. When choosing the best tool head, you must consider one that meets your needs and functions accordingly. The head significantly influences the entire process and its results.

Benefits of 3 axis CNC milling machines

3 axis CNC milling machines are quite versatile. For this reason, they are used for producing fixtures, clamps, and stocks, among other products. Some of the best CNC milling machines have an automatic tool changer. The role of this part is to allow the completion of multiple tasks on a single work tool. It also saves a lot of time. Additional coding will also allow you to upgrade to a 3 axis CNC machine. Doing this gives the machine the ability to move the axes at the same time.

Conclusion

CNC milling is an incredible manufacturing technique with a wide range of benefits. It can be used as a prototyping technique. This is the creation of drafts of a concept for testing before it is produced in mass. CNC milling can be applied in a wide range of industries. It can also be used for creating products of varying shapes and sizes. Other than 3 axis CNC milling machines, there are also 4 and 5 axis machines. The more axes, the more the efficiency and benefits of the product.