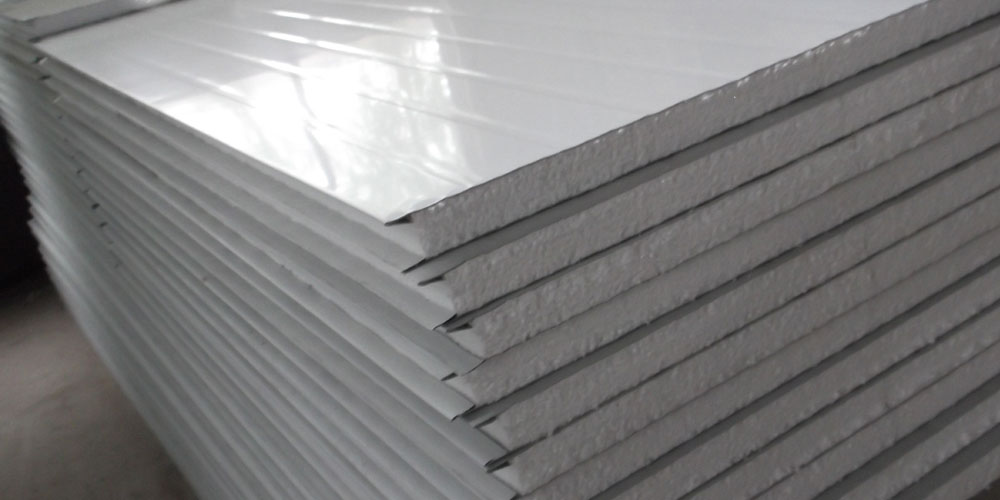

A sandwich panel is a protective system that keeps external factors from interfering with the integrity of a building. The panels provide convenience and cost-efficiency by protecting buildings from external factors. Sandwich panels are used for cladding roofs and external walls of buildings. They can also be used as insulation for internal walls and cold storage facilities. They are applied for both residential and industrial buildings. The market features several types of sandwich panels on the market, and the eps panel is one of the many. In this post, we look at eps sandwich panels in depth.

What is an eps sandwich panel?

An eps sandwich panel uses polystyrene foam as its core material. It also uses a color steel plate on its surface sides, pressing, and is bonded using high-strength adhesive. All these elements form a lightweight wall and roof panel used on buildings. These sandwich panels can be used for heat insulation and thermal resistance. In simple terms, eps sandwich panels are insulation materials with load-bearing, waterproof, and economic qualities.

Characteristics of eps sandwich panels

Below are some defining characteristics for eps sandwich panels;

1. Thickness

According to scientific data, eps sandwich panels feature the same thickness as 75CM brick walls. Their thickness allows you to apply them for heat insulation and noise protection. Their thickness is also responsible for their durability.

2. Sound insulation and heat insulation

Eps sandwich panels are great sound insulation products. This is because of the materials from which they are manufactured. The same thing can be said about their heat insulation features.

3. Fire retardation

These sandwich panels are also fire retardant. They can achieve a B2 class fire rating. When they are subjected to flames, they form carbon and a layer of graphite foam on their surface. The graphite foal layer protects the entire structure from being consumed by flames. The sandwich panels also do not crimp, drop or melt due to high temperatures.

4. Strength

Eps sandwich panels are very strong because they use steel structures as edge seals which enhance their strength. They also enhance their durability by preventing damage when the panels are exposed to harsh conditions.

5. Corrosion resistance

The sandwich panels are also resistant to corrosion. This is because they are made from corrosion-resistant materials like coated steel.

6. Durability

These panels are designed to resist inorganic acids, organic solvents, and acids. This increases their lifespan. Additionally, they do not age from long-term exposure to sunlight. This makes them great roofing panels as they are highly aging-resistant.

7. Aesthetics

These sandwich panels are quite attractive. They come in bright colors and feature a good overall effect. For this reason, they are highly applied in industrial or commercial facilities. When applied, they do not require further decoration.

Conclusion

Eps sandwich panels can be applied in a wide range of areas. For instance, they can be used for temporary facilities like warehouses, workshops, exhibition facilities, and movable homes, to name a few. They can also be applied in industrial buildings. These panels are also quite easy to install. This makes their application effortless.