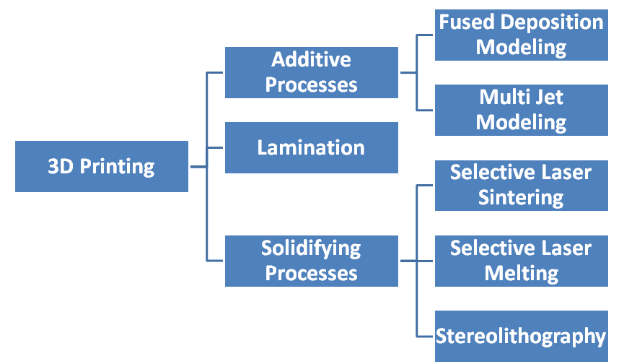

There are many different ways to render a model in 3D today. This is because of the many different needs and roles that these models have to fill. Do you need a very solid, rugged component that can withstand significant abuse? Well, there’s a type of 3D printer to fill that need. Do you need models that are fabricated to near perfection? There’s another type of 3D printer that does that perfectly!

It is important to know about all the major types of 3D printers. Why? Well, that’s the only way to find the perfect machine to suit your project(s). Were going to go through a couple of these printers and discuss their techniques and functions.

(Fused deposition modeling) FDM

Arguably the most popular, and most adaptable method of 3D printing. These printers construct models from the bottom right to the top level. This occurs in layers. The modeling process is achieved through heating and extruding thermoplastic filament to form each layer. Slicers(specialized 3D printing software) derive each layer of the model from CAD blueprints, and these layer by layer blueprints direct the nozzle, printing each layer.

SLA(stereolithography)

SLA printing, unlike other more conventional forms of printing, starts with an excess of liquid plastic. This liquid is placed in a tank in the printer and then layer by layer, the model is fabricated. The liquid plastic is hardened by a laser and is hardened on a flat surface called the stage. After the first layer of the model is hardened, the stage drops down by less than a millimeter and the process is repeated.

DLP(digital light processing)

This type of printer is very similar to the SLA printer in that it utilizes high-frequency light to harden a liquid polymer to create a model. However, this type of printer depends on an LCD panel to produce the light needed to harden the resin. The resin hardens quite fast upon exposure to high-frequency light. This form of printing tends to be significantly faster than FDM printing.

SLS(selective laser sintering)

SLS printing makes use of a laser to form models. The models printed with this technique are usually very rigid and tough. The biggest difference between SLS an SLA is that instead of liquid resin, SLS printing makes use of powdered material in a vat. This type of printing removes the need for support structures. This type of printer is very expensive as it requires extremely high powered lasers.

These 3D printing techniques aren’t the only ones to exist. SLM(selective laser melting), LOM(laminate object manufacturing) and Digital Beam Melting are examples of other 3D printing techniques. Over time, these techniques proved to be lacking. They were either overshadowed by more effective methods of printing or proved to be economically impractical. Eventually, these printing methods faded away.

Each of the 3D printing techniques discussed is the best at what it sets out to do. As a result of progress in technology, these techniques have become more and more available. They are also become cheaper to use. That you’re reading this means that you are that much closer to finding the perfect 3D printer for you.